API610 Oh2 Fze Overhung End Suction Centrifugal Oil Pump for Chemical Plants

Overview API610 Oh2 Fze Overhung End Suction Centrifugal Oil Pump for Chemical Plants Product DescriptionConform to desi

Basic Info

| Model NO. | FZE |

| Position of Pump Shaft | Horizontal Pump |

| Pump Casing Combined | Horizontal Split Pumps |

| Mounting Height | Suction Centrifugal |

| Impeller | Closed |

| Usage | Pump, Pumps, Circulating Pump, Oil Pump |

| Capacity | 3~2600m3/H |

| Head | 4~300m |

| Pressure | ~5.0MPa |

| Temperature | -80~450 Degrees |

| Standard | API610 |

| Rotation Speed | 1450, 2900 |

| Package | Plywood Box |

| Transport Package | Plywood Box |

| Trademark | Feiyue |

| Origin | Jiangsu, China |

| Production Capacity | 5000 |

Product Description

API610 Oh2 Fze Overhung End Suction Centrifugal Oil Pump for Chemical PlantsProduct DescriptionConform to design standard of API610

- Capacities: To 1920m³/h (8450 USGPM)

- Heads: To 380 m (1250 ft)

- Max Working Pressure: Consistent with pressure rating of ANSI Class 300 flanges as a standard. Higher pressure ratings are available.

- Rotation: Clockwise viewed from coupling end

- Impeller: Enclosed

- Temperatures: -100°C to 450°C (-150° to 850°F)

- Flanges: ANSI Class 300 as Standard

- Nozzles: End-Top/Top-Top

- Stuffing Box: Suitable for Conventional packing & mechanical seal

Our basic API 610 type OH2 pumps are centre line mounted, single stage, overhung pumps with a single bearing housing. The pump and motor are flexibly coupled and installed on a common baseplate. The coupling design allow removal of the back pull-out assembly without disturbing the driver, coupling hubs or casing.

ApplicationThis series of product is applicable to convey clean or particle-contained liquid, neutral or corrosive media at low or high temperature,mainly used in the fields of petroleum processing, petrochemical, papermaking, coal processing, food, pharmacy. environmental protection.

Design Features- Type: OH2

- Centerline supported heavy duty design

- Back pull-out casing

- Full compliance with API 610 specifications

- All components have been designed for maximum parts interchangeability

- Flexibility of design handles wide range of liquids

- All sizes stocked for last shipment

- Low NPSH performance

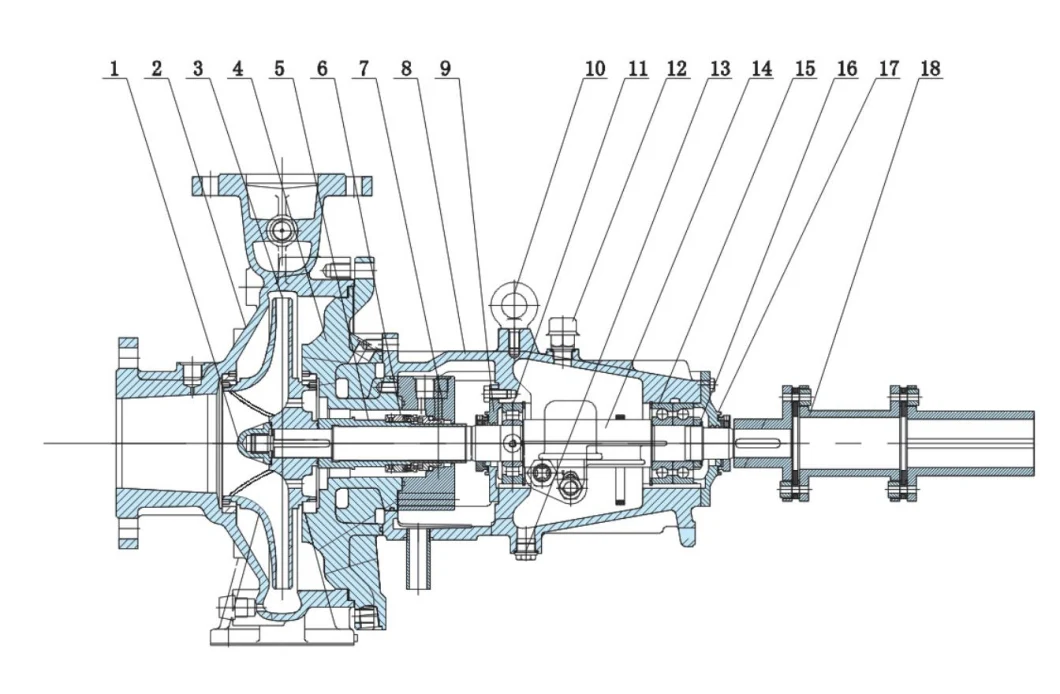

| 1 | Impeller nut | 2 | Pump body | 3 | Impeller | 4 | Pump cover | 5 | Axle sleeve | 6 | Machine seal |

| 7 | Seal cover | 8 | Bearing box | 9 | Front axle bearing cover | 10 | Suspension loop | 11 | Front bearing | 12 | Air chamber |

| 13 | Oil draining bolt | 14 | Axle | 15 | After bearing | 16 | Lock nut | 17 | Rear axle bearing cover | 18 | Coupling |

Performance parameters of the table

Company Profile

Send to us