High Viscosity External Magnetic Drive Micro Gear Metering Pump for Chemical and Biological Industry

Overview Product Description This series can solve the working situation of 4 - 48L/min flow, 0.5-25bar pressure differe

Basic Info

| Model NO. | MRE34/37 |

| Type | Arc Gear Pump |

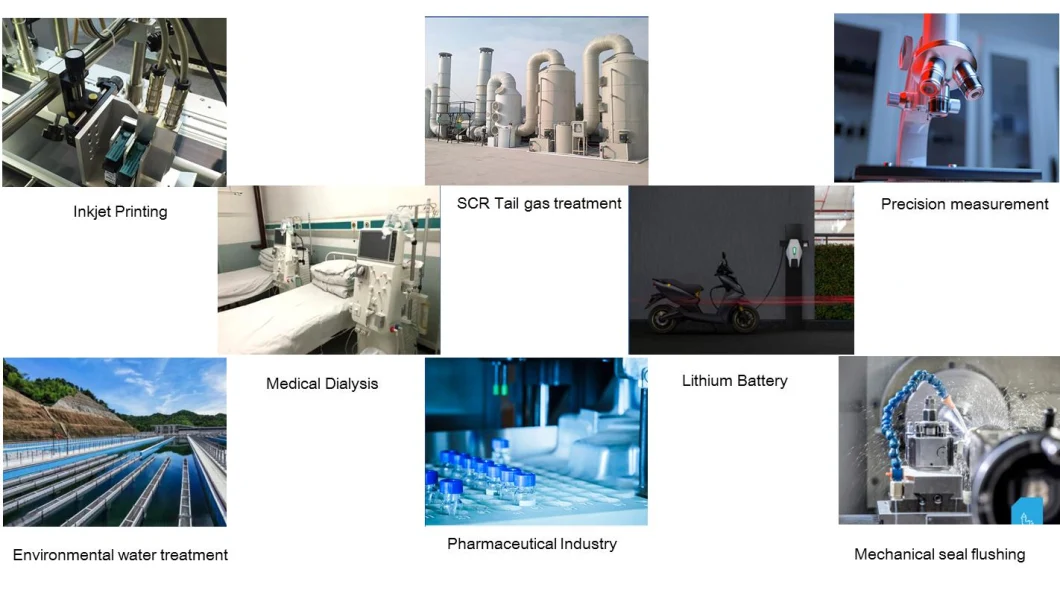

| Applications | Machinery Manufacturing |

| Certification | CE, ISO |

| Model | Mre34/37 |

| Flow Rate | 12.75-48.45L/Min |

| Viscosity | 0.4-3000 Cps |

| Pressure Differential | 0-25.5 Bar |

| Max. Temperature | -20 to 180 ºC |

| Pump Body Material | SS304/SS316L |

| Gear | Reinforced Peek |

| Shaft | Nano-Ceramic |

| Certificate | CE, ISO9001, Nippon Kaiji Kyokai |

| Motor | AC, BLDC, Servo, Inverter, Ex-Proof Motor |

| Capacity | 5000 Sets |

| Transport Package | Plywood Case |

| Trademark | JONSN |

| Origin | Ganzhou, China |

| Production Capacity | 5000 |

Product Description

This series can solve the working situation of 4 - 48L/min flow, 0.5-25bar pressure difference and 0.4-3000m.Pas viscosity (similar to water).The pump can withstand a pressure of 6 MPa.

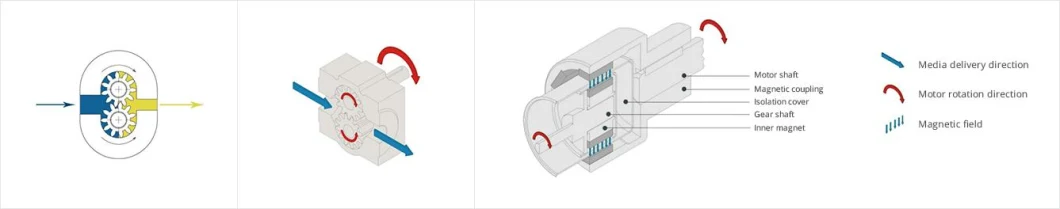

Working Principle

- Flow range: 0.001-48.5 l/m

- Inlet pressure: -0.9-10 bar

- Pressure difference: 0-25.5 bar (depends on material viscosity)

- Temperature: -20-160 (other temperature customized)

- Viscosity range: 0.4-3000 cps

- Max. gravity: 1.8

- Motor options: AC motor, Brushless DC motor, Servo motor, Inverter explosion-proof motor

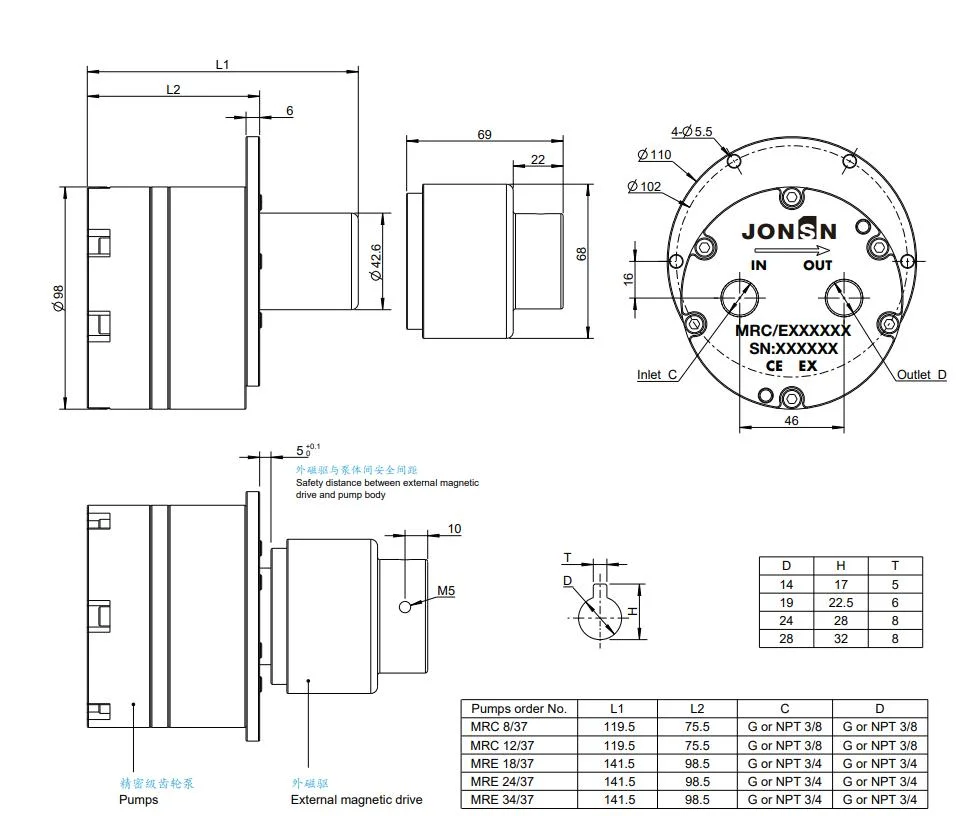

- Inlet & outlet thread: NPT1/8", 1/4", 3/8", 1/2", 3/4"

- Non-standard customize: OEM machine ancillary, and servo system.

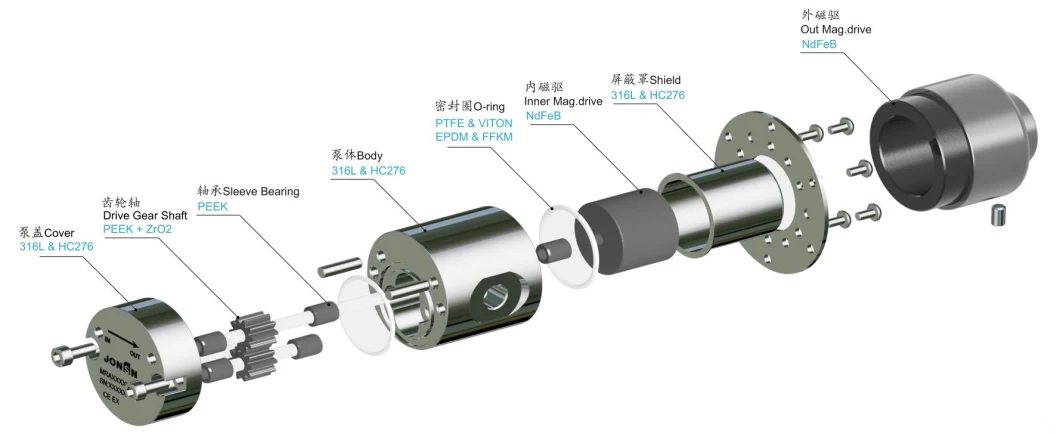

Explosive view:

- Pulsation-free precise converying - Positive displacement pump provide continuous precise conveying through the gears, converying accuracy can reach +/-0.5% with the servo or stepper motor.

- Strong vacuum suction, high pressure and smooth delivery, help to realize the low viscosity liquid delivery in middle & high pressure.

- Zero leakage - Magnetic drive and static O-ring ensure the inside pump medium isolated from the outside.

- Excellent workmanship and MD - The designs optimize the gear shaft, pump body flow channel, and make it longer service life. We have lean manufacturing idea and adopt advanced processing technology & exquisite workmanship. It is an external gearing pump designed & manufactured for high-end application.

- Model selection specialization - We have rich operating experience in thousands of micro gear pump, accumulate lots of experiment data, specialize in selection evaluation, and formulate solution to reduce risks for you.

Advantages:

- Wide displacement range: 0.18ml/r-17ml/r(Meet the request of most micro flow).

- High pressure differential: 10-25.5 bar(Normal), maximum 4Mpa.

- Long service life: Gear& shaft adopt reinforced PEEK gears + high strength nano ceramic shafts combination, which are more wear resistant and greatly improved the service life of the pump. High gear consistency and interchangeability: Processed by Japanese precision CNC hobbling machine, gear consistency and interchangeability is high.

- Temperature range: -120ºC to 180ºC, we use high-performance magnetic material, improve inner magnet over molding process, completely solve the problem of high temperature thermal expansion and bulging.

- High wear-resistance: By the use of high quality bearing grade PEEK modified material (confidential formula), relevant data is available. Wear resistance is ☆☆☆☆☆ by using of nano-ceramic shaft while using SS316L is ☆, and ceramic is ☆☆.

- Long time operated under 100ºC ambient temperature.

- Strong ability of industry application and accurate pump selection data analysis by software instead of experience only.

- Comprehensive testing ability for all elements and the testing result is traceable in the systems.

- High Gear accuracy testing capability by the German Winzer Gear Testing device.

- Service life: >20000 hours while others normally 6000-8000 hours.

Non-standard product please contact our sales for detailed information.

We offer unique solution of pump to each individual working condition.

OUR SERVICE

Send to us