15m³ /Hr High Pressure High Temperature Vertical Pump Immersion Pump Manufacturing

Basic Info

| Model NO. | HPS Series |

| Certification | CE, ISO |

| Model | HPS-15-10-Ss-1000 |

| Max. Flow Rate | 15 Ton/Hr -50 Ton/Hr |

| Max. Viscosity | 2500 Cps |

| Max. Head | 10m - 14m |

| Pump Body Material | Stainless Steel |

| Certificate | CE, ISO9001 |

| Capacity | 5000 Sets |

| Motor | Electric Motor |

| Medium | High Viscosity Liqud |

| Pump Length | 700mm, 1000mm, 1200mm and Customize |

| Submerged Depth | 1.0-2.5m |

| Transport Package | Carton Box / Plywood Case |

| Trademark | JONSN |

| Origin | Ganzhou, China |

| Production Capacity | 5000 |

Product Description

Product Description

The submersion pump specially design for the liquid like strong oxidant liquids, leaching liquids. The motor is usually above the liquid level, and pump body below the liquid level,. The pump body is mostly made of engineering plastics or fluoroplastics.

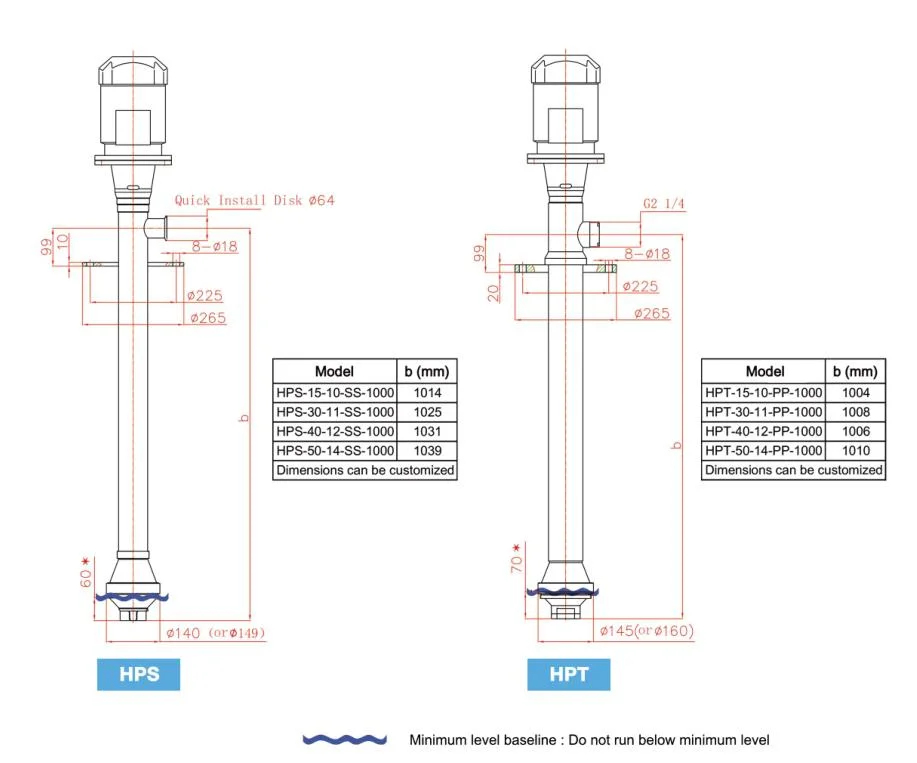

Product parameters

1. Flow rate: 15 Ton/hr - 50 Ton/hr2. Delivery head: 10-14m3. Max. Visocisty: 1200-2500 cps4. Max. Dia of pump line: 140-149 mm5. Outlet Dia: 38-50 mm6. Drive: Electric motor7. Immersion length: 700mm, 1000mm, 1200mm, Non-standard customSecure Features & Advantages

Features:

•Single tube design with compact dimension and light weight.

•Various of pump materials: SS316L, engineer plastic PPHT, high corrosion resistant

fluoroplastics PVDF, applicable for various of different working conditions.

•Thanks to its light weight, this pump can be installed not only in fixed site, but also as a

mobile pump in multiple locations. It is easy to maintain.

•Built-in copper sleeved sliding bearing and self lubricating system eliminates rely of

sliding bearing on external lubricants. Lighter abrasion avoids replacement of sliding

bearing during pump's life cycle.

•High efficiency of energy saving and application of three dimensional impeller makes

the submerged pump gain bigger flow rate from smaller power.

•The pump responds quickly and can be powered up to dispense liquid.

•External float switches or liquid level control cabinets can be connected to automatically

control the start and stop of the pump; a pump protector can also be used to prevent the

impact of idling, blocking and overloading on the pump.

•Various outlet connections, i.e. plug-in hose connection, threaded or flanged hard pipe

connection.

•Various sizes of submerged depth, 1.0m, 1.5m, 2.0m, 2.5m, non-standard

customization is acceptable.

1. High quality material: SS pump use Janpan NSK bearing, PVDF pump use imported USA HC276 with high corrosion resistance. 2. Sanitary structure for stainless steel pump makes it applicable for food industry.

3. Easy to replace and maintain: Motor and pump adopt adjustable installation structure; a pump can be replaced with different motors easily in 5-10mins.

4. Leakage-free and high pressure shielding design, ensure its safety for dangerous liquid transfer. And lower down its maintenance cost. 5. High performance & low cost: With decades years experience of international branded high quality pump, set factory in Ganzhou, Jiangxi, we optimize the design and production make it to be high performance with lower cost.

APPLICATIONS

Pharmaceutical plants: E.g. strong oxidant liquids, leaching liquids. The motor is usually above the liquid level, and pump body below the liquid level,. The pump body is mostly made of engineering plastics or fluoroplastics.•Desalination manufacturing plant: Seawater is erosive, if use submersible pumps or submersible sewage pumps, their cable lines are soaked under the liquid constantly, will also gradually corrode by diazotization reaction, and the safety performance becomes not high. With submersible pumps, the difficulty of having the motor and cable under the liquid is avoided.•Urban sewage treatment plant discharge systems: Sewage discharge from underground, basement, human defense system drainage stations, hospitals, hotels, high-rise buildings.•Plating and pickling industry: Circulation and transport of plating pickling solution, tank cleaning of plating tanks.•Water treatment and environmental protection industry: All kinds of sewage with impurities can be transported.•Rare earth non-ferrous metal wet smelting industry: Especially suitable for the transport of various acids, alkalis, corrosive slurries, electrolytes, waste acids, sewage from the wet smelting processing of lead, zinc, gold, silver, copper, manganese, cobalt, rare earth and other wet smelting.•Pesticides, dyestuffs, fine chemical industry: Can transport clear liquids containing dilute acids, alkaline liquids, mixed acids.•Sulphuric acid and phosphate fertilizer industry: transport of dilute acid, mother liquor, fluorosilicic acid with silica gel, phosphoric acid slurry and other media.PERFORMANCE CURVE

PUMPS&MOTOR DRAWING

DRUM PUMP ACCESSORIES

| 1. Quick clamp | 6. Hose | 11. Hose with live joint | 16. Air filter |

| 2. Te-flon gasket | 7. Threaded hose connector | 12. Pump fixator | 17. Dosing gun |

| 3. Threaded quick connector | 8. Reducer union | 13. Equipotential ground wire | 18. Adaptor joints |

| 4. Hose quick connector | 9. Quick combination connector | 14. Stainer | 19. Drain pipe |

| 5. Hose clamp | 10. Flowmeter | 15. Wall mounting |

PARAMETERS

OUR SERVICE